Robotic Duct Cleaning

So, what particular issue within HVAC systems could be solved by better duct cleaning? It comes down to the fact that if air ducts within a building are not completely cleaned of debris and dust, they can become host to bacteria and fungi, which can then be circulated through the air and cause illness to people within that building.

Not only did HVAC systems require a better method of cleaning in order to prevent the spread of infectious disease. A comprehensive duct cleaning method was also essential in the fight against airborne allergies caused by dust and pollen.

Importance of Robotic Duct Cleaning

This discovery prompted duct cleaning experts within the cleaning industry to realise that they could deploy robots to solve this issue and improve infection prevention. Firstly, before a cleaning solution was developed, they used small robots with cameras to travel through air duct systems and record what they saw.

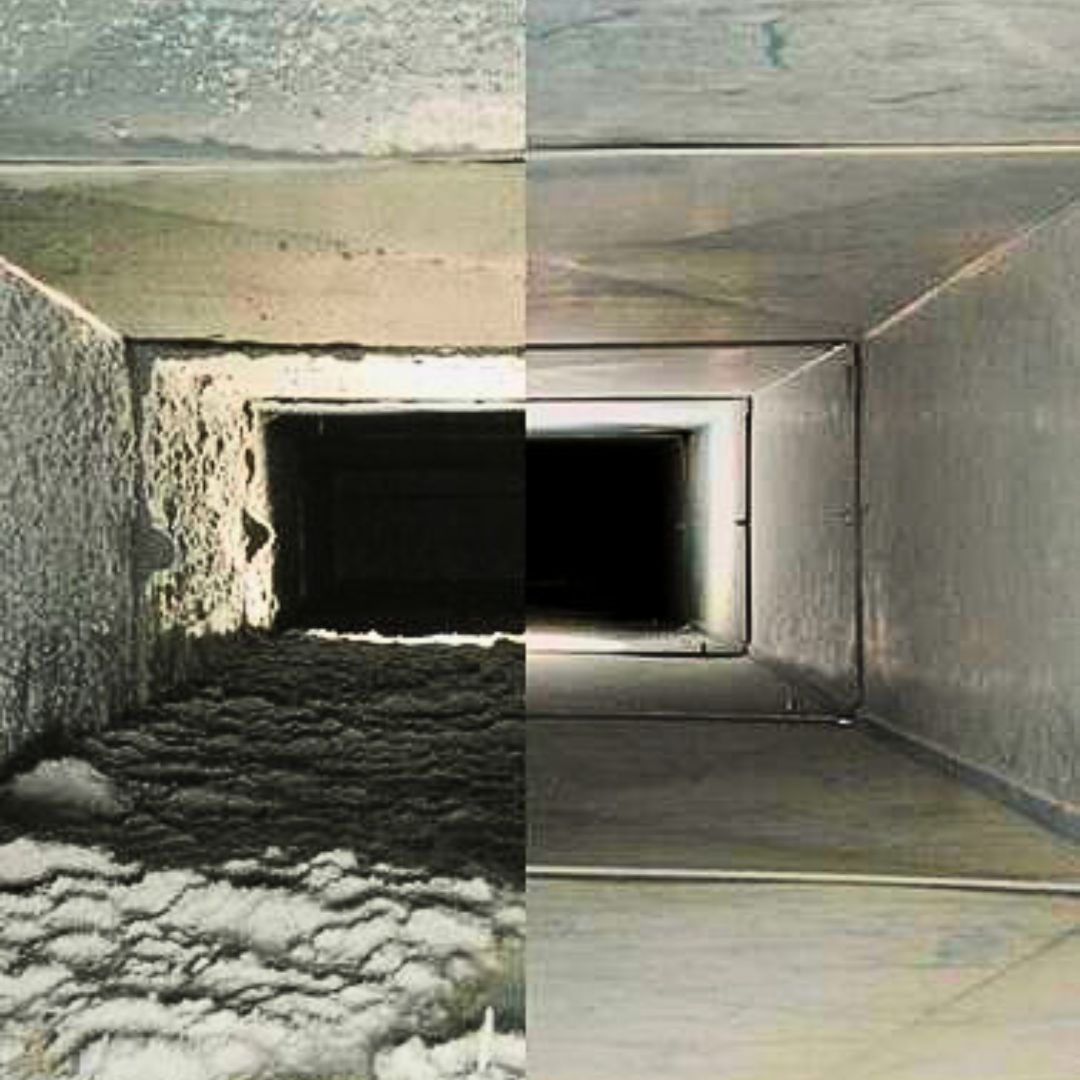

This footage often proved a build-up of debris and dust was present within the ducts and that something needed to be done about it. Proper cleaning and maintenance of HVAC systems were required to improve air purification. The next step was to develop robotic technology to clean the ducts, a job that was never performed easily by humans.

Advantages

- Saves energy cost.

- Less time-consuming.

- New duct cleaning robots not only made the job quicker and easier, they also save on costs.

- Robots can manoeuvre around obstacles and fit into smaller apertures than traditional cleaning tools.

- Dust and other debris get removed which make HVAC systems work harder.

- With vacuuming, rotary brushing and air sweeping, we also do ozone sterilization of ducts after cleaning. Ozone is a powerful oxidant that removes Odour, Voc’s and even fungi by oxidation.

Applications

- Office buildings

- Airports

- Hospitals

- Pharmaceuticals Industry

- Food Processing Industry

- Hotels

Image of Before Cleaning And After Cleaning

Note –

Not all Usha Filters products are washable, as due to washing filter media fibers get weak and damaged which may later affect the filter’s poor performance. Please consult the manufacturer for the same. We provide a detailed cleaning manual.

Filters can be made in various tailor-made sizes and types per customer requirements concerning their application, fitment, Usage, desired flow, particulate matter concentration load, and filtration class required.